Since the occurrence of the novel corona virus, masks have become a scarce material for prevention and control of epidemics at home and abroad. Masks are not only a powerful guarantee for epidemic prevention and control, but also a basic condition for the orderly consumption of work and production. In response to the shortage of national mask production equipment, Qingdao Fanya Computerized Machinery Co., Ltd. cooperated with a local intelligent equipment manufacturing company and launched a fully automatic mask production line to provide efficient automation for the production of anti-epidemic materials solutions and contribute to the strength of their own to fight the epidemic!

Product Introduction

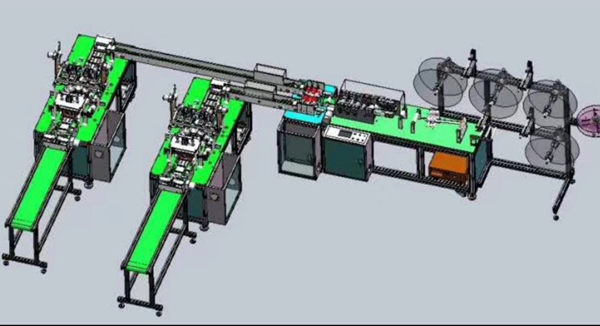

Fully automatic high-efficiency mask production line, consisting of automatic raw material conveying system, folding forming system, ear band welding system, and blanking system; suitable for multi-layer PP non-woven fabric, activated carbon and filter material, completed by ultrasonic welding and automatic edge sealing The entire production process of flat masks from raw material rolls to mask forming realizes the full automation of mask production from materials to finished products. It can produce 6000 ~ 8000 masks per hour.

The masks produced by this production line have the characteristics of comfortable wearing, no pressure, good filtering effect, etc .; they can be used in medical, electronics, mining, construction and other industries.

Design Features

1. The entire production line has the characteristics of high automation and high production efficiency.

2. The whole machine adopts aluminum alloy structure, which is beautiful and solid without rust.

3. Computer PLC programming control, servo drive, high precision and good stability.

4. Automatic tension control of raw materials to ensure that the tension of raw materials is balanced.

5. Multi-point photoelectric (optical fiber) detection and feeding system, automatic alarm when abnormal, avoid mistakes and reduce waste.

6. Folding molding system can effectively reduce product deformation.

7. This production line can be used with automatic mask packaging line to realize unmanned operation from material to finished product to packaging. Technical Parameters

TJKZ-P product standard parameters (excluding bagging machine)

Model TJKZ-P

Mask Type Disposable Ear Band Flat Mask

Designed capacity 100 ~ 130 pcs / min

Body Material Aluminum Alloy

Control method: PLC fully automatic control

Detection method Photoelectric detection

Working voltage AC 220V / 50HZ

Working pressure 0.5 ~ 0.7Mpa (flow: about 300L / min)

Power consumption 14KW

Overall dimensions (mm) 6500 * 3500 * 1500

Equipment quality (KG) 1500

Applicable Products

It is used for the automatic production of disposable flat (three-layer / four-layer) masks. The materials used are fiber non-woven fabrics professionally used for medical and health. Filter melt spray cloth is made by ultrasonic fusion, and the filtering effect is up to 99%. Supporting Materials

1. Two to three layers of non-woven fabric (25-30 grams).

2. Dissolve spray cloth.

3. Nose bridge support: 5.0mm * 0.55mrr.

4. Ear band: 2.5 ~ 3.0mm diameter round band.

Production Process

1. Check the equipment and check for abnormalities such as voltage and air pressure. Prepare raw materials according to size requirements.

2. Non-woven fabric, melt blown non woven fabrics, ear band and other materials should be placed on the equipment as required.

3. Production line operation produces mask body and ear band welding.

4. Packing according to the number of pieces (manual or automatic line packaging).

5. Sterilization and disinfection using equipment (sterilization and disinfection for medical grade masks for 12 hours).

Installation Requirements

1. Ground load: ≥500KG / m2.

2. Operating environment: It is required to be a dust-free workshop (with a cleanliness of not less than 100,000), the temperature is 10 ~ 35 ℃, and the humidity is 5 ~ 35% HR; there is no flammable and corrosive gas in the workshop.

|